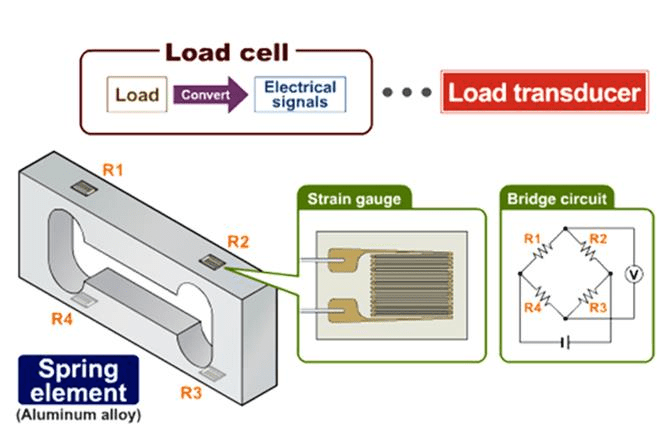

In physical measurement, the strain is the amount of deformation experienced due to an applied force in a particular material. In simple words, the strain is any force or pressure tending to alter the shape and the sensor used to measure this deformation or change in shape is known as Strain Gauge sensor.

When is applied force is sensed in terms of change in resistance, the sensor is known as Resistive strain gauge sensor?

Where Strain Gauge sensor is used?

The strain gauge has been in use for many industrial applications for for the electrical measurement of physical parameters such as force, pressure, tension and weight. It is a basic universal sensing element for sensors such

- Pressure sensors,

- Torque sensors,

- Load cells,

- Position sensors, etc.

Types of strain Gauge

- Bonded Resistance Strain Gauges

- Foil resistance Strain gauges

- Carbon resistive Strain gauge

- Semiconductor Strain Gauges

Strain Gauge Selection

The main considerations in strain gauge selection are :

- Operating temperature

- Stability requirements

- Nature of the strain to be detected

Apart from this, selection of the right carrier material, adhesive, grid alloy, and protective coating also plays an major role in the success of the application. once you finalise the type you also needs to cross check some prime considerations

- Gauge Length

- Carrier Material

- Grid Resistance

- Number of Gages in Gauge Pattern

- Arrangement of Gages in Gauge Pattern

- Strain-Sensitive Alloy Gauge Width

- Solder Tab Type

- Configuration of Solder Tab

Strain Gauge Accuracy

For practice, to use the strain gauge as a practical sensor, we have restrictions imposed by the elastic limits of the gauge material and the test object, we must measure extremely small resistance changes with high accuracy. For Such high precision, Wheatstone bridge is best suitable option we have. Accuracy class of strain gauge is depending on manufacturers. for example, BF350-3AA resistive strain gauge come with Accuracy class 0.02 means that the measurement has an error rate of 0.02% .

Some most popular Strain Gauge Applications

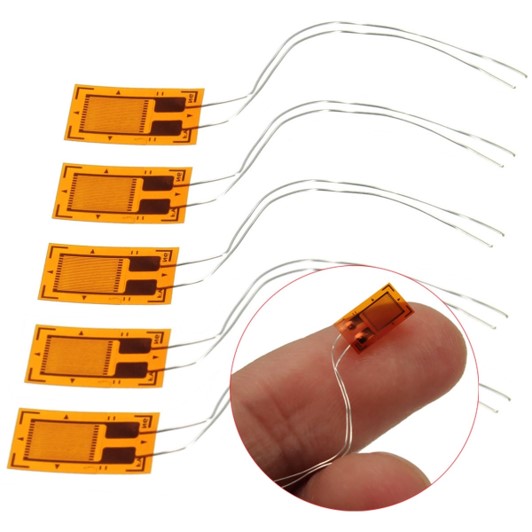

1. BF350-3AA

Precision resistive strain gauge for the pressure sensor, load cell, deformation measurement. BF350-3AA is widely used in product development, student experiments, maintenance, production, etc. the key features of BF350 are high accuracy, good stability, easy to use and suitable for 0.02 level sensor.

Type: BF350-3AA

Resistance: 349.8 ±0.1Ω

Sensitivity coefficient (gauge factor): 2.0 – 2.20

Accuracy class: 0.02

Strain limit: 2.0% (2000 macrostrain)

Monolithic size: 7.1mm * 4.5mm

Materials used for making BF350 conductive material is Constantan, copper-nickel alloy 55% copper or 45% nickel as it provides constant resistance over temperature. In substrate backing modified phenolic resin foil is used.

How to Use

The size of BF350-3AA is 7.1mm * 4.5mm which is too small for handling, we always recommend pre solder tab with flexible wire which is easy to install. the Applications surface must be polished, remove any oxides, residues before applying adhesive. We recommend adhesives like epoxy glue hot curing adhesive (H-610 or equivalent) for long term use and for short term Cyanoacrylate glues is best.

BF350-3AA Arduino

BF350 sensor should be used in a Wheatstone bridge configuration to get change in resistance accurately. To use it with Arduino we are using our HX711 digital bridge sensor interface module. HX711 is a precision 24-bit analog- to-digital converter (ADC) designed for weigh. Alternatively, if we need only relative measurements that are required then we need a strain gauge amplifier that includes BF350-AAA sensor and can be connected directly to a Arduino microcontroller ADC input.